CLEANROOM

“Cleanroom” is an enclosed room that controls the number of airborne particles. The construction uses a method that reduces the number of imported increments and particles. The related variables include temperature, humidity, and pressure in various types of industrial applications, such as:

• Food & Drink Industry

• Pharmaceutical, Meditec & Lab Room

• PCB & Electronic & Computer Industry

• Packaging Industry

• Cosmetics industry

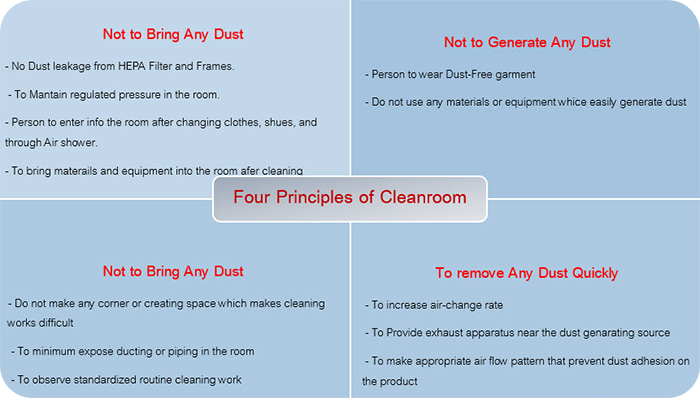

Generally, pollutants or particles in the air consist of living and non-living particles. Cleanrooms in the biology, medicine, and food industry, focus on preventing microorganisms, such as bacteria, fungi, yeasts, viruses, and their spores by using technology; The HEPA filter (high-efficiency particulate absorbing filter) removes particles of 0.3-10 microns with 99.97% efficiency.

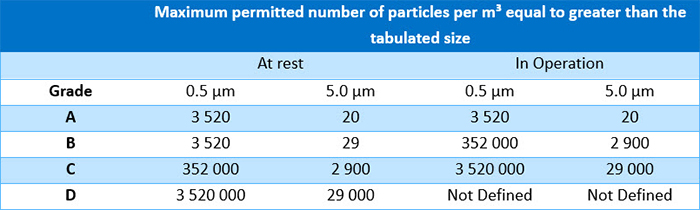

CLEANROOM STANDARD

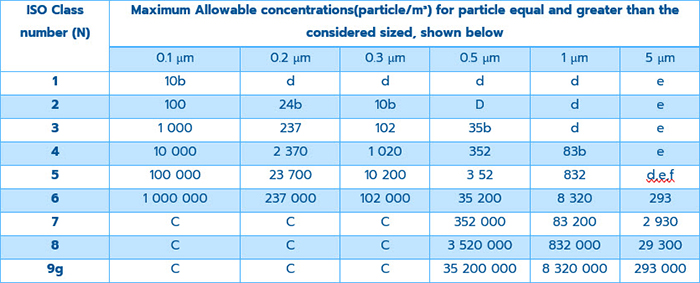

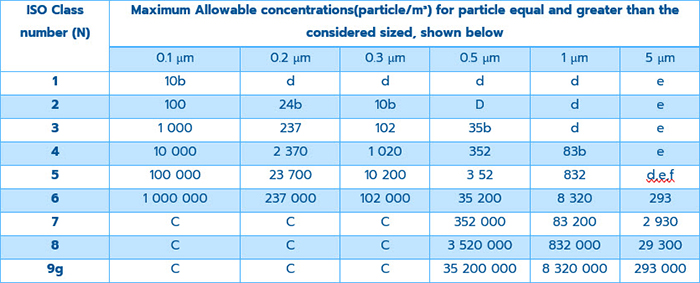

The new classification table

Table 1- Classification of air cleanliness by particle concentration

a) All concentrations in the table are cumulative, e.g. for ISO Class 5, the 10,200 particles shown at 0.3 um include all particles equal to and greater than this size.

b) These concentrations will lead to larde air sample volumes for classification. Sequential sampling procedure may be applied; see Annex D.

c) Concentration limits are not applicable in this region of the table due to very high particle concentration.

d) Sampling and statistical limitations for particles in low concentrations make classification inappropriate.

e) Sample collection limitations for both particles in low concentration and sizes greater than 1 um make classification at this particle size inappropriate, due to potential particle losses in the sampling system.

f) In order to specify this particle size in association with ISO Class 5. The macroparticle descriptor M maybe adapted and used in conjunction with at least one other particle size. (See C.7.)

g) This class is only applicable for the in-operation state.

ISO 14644-1 ; 2015

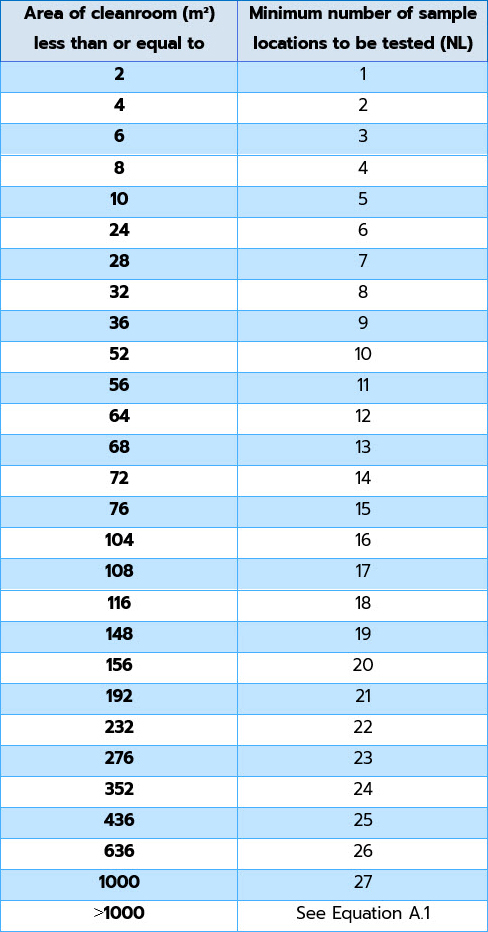

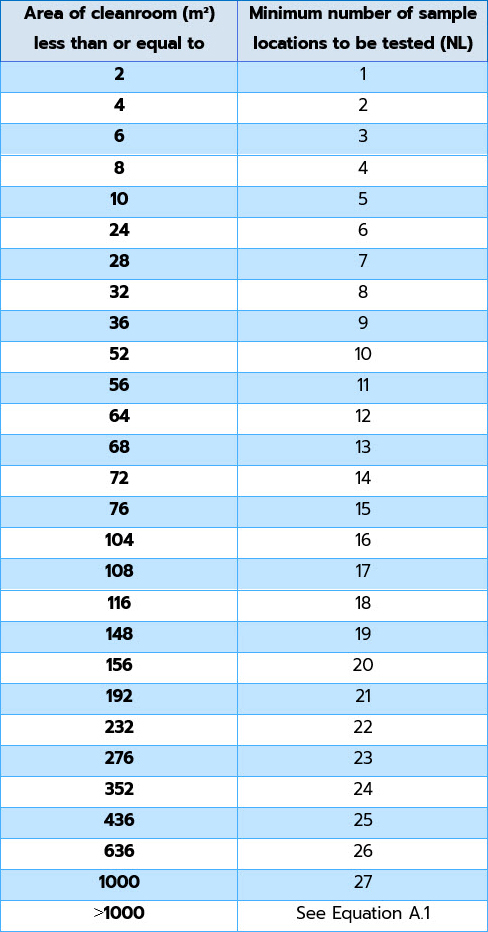

Requires minimum sampling location

Table A.1 -Sample Location Related to cleanroom area

1. Determine the number of sample locations NL from table A1.

2. Divide the room/zone into NL areas equally.

3. Select the representative sampling locations in each zone (not under undiffused HEPA filter terminals.)

4. Take a sample from each location (sample size according to the existing standard)

5. Average the samples from each location if multiple samples are taken.

6. If all measured concentrations (or averaged) comply to the class limit, the classification is met.

7. For locations larger than 1000 m2, refer to equation A.1.

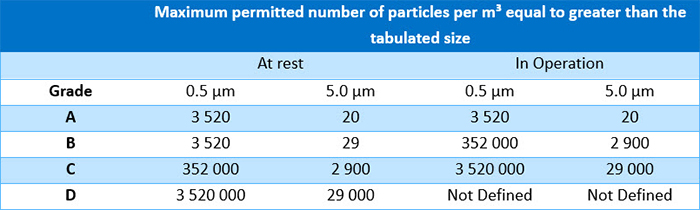

Dealing with New Standards

EN ISO 14644-1 : 2015

(approved on 15th December 2015)

These Value will be clearly outside the revised EN ISO standard. There is a rationale in the standard to extrapolated the use of the Marco – particle descriptor Good science would remove these levels.

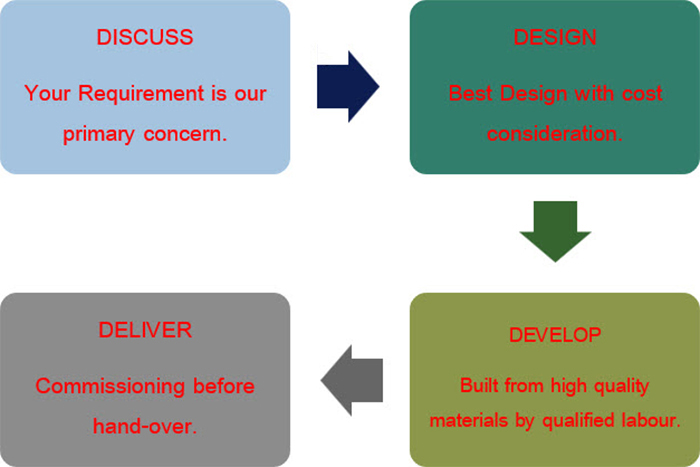

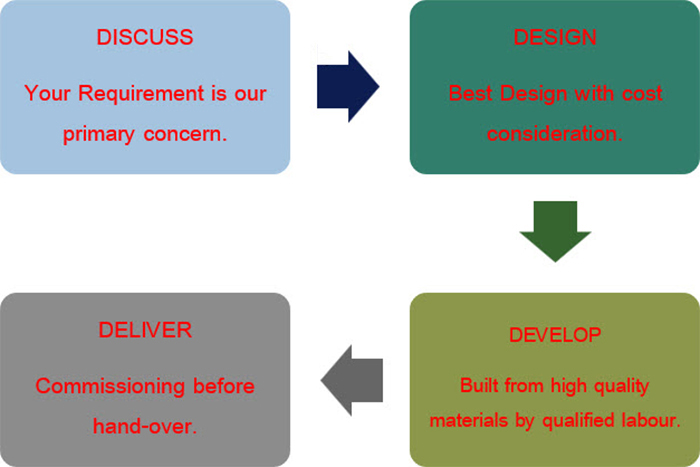

Steps to Creating the Cleanrooms according to Customers’ Needs

DISCUSS

Your Requirement is our primary concern.

To construct the most effective cleanroom for the customers, we gather concerns and details to cater to your requirements, starting with a conversation between the room users and our team of professional design engineers. This will let us know customers' needs such as:

1. General specifications of the room, including space, temperature, humidity, lighting, or other factors that Customers want to control

2. The level of cleanliness of the room from ISO14644 Class 1-9 or FED STD 209E Class 1-1OOK, which the choice of cleanliness class depends on the customer's intended use.

3. Additional requirements in case customers want Clean Room to pass various certification standards such as FDA Standard, GMP Standard, etc.

DESIGN

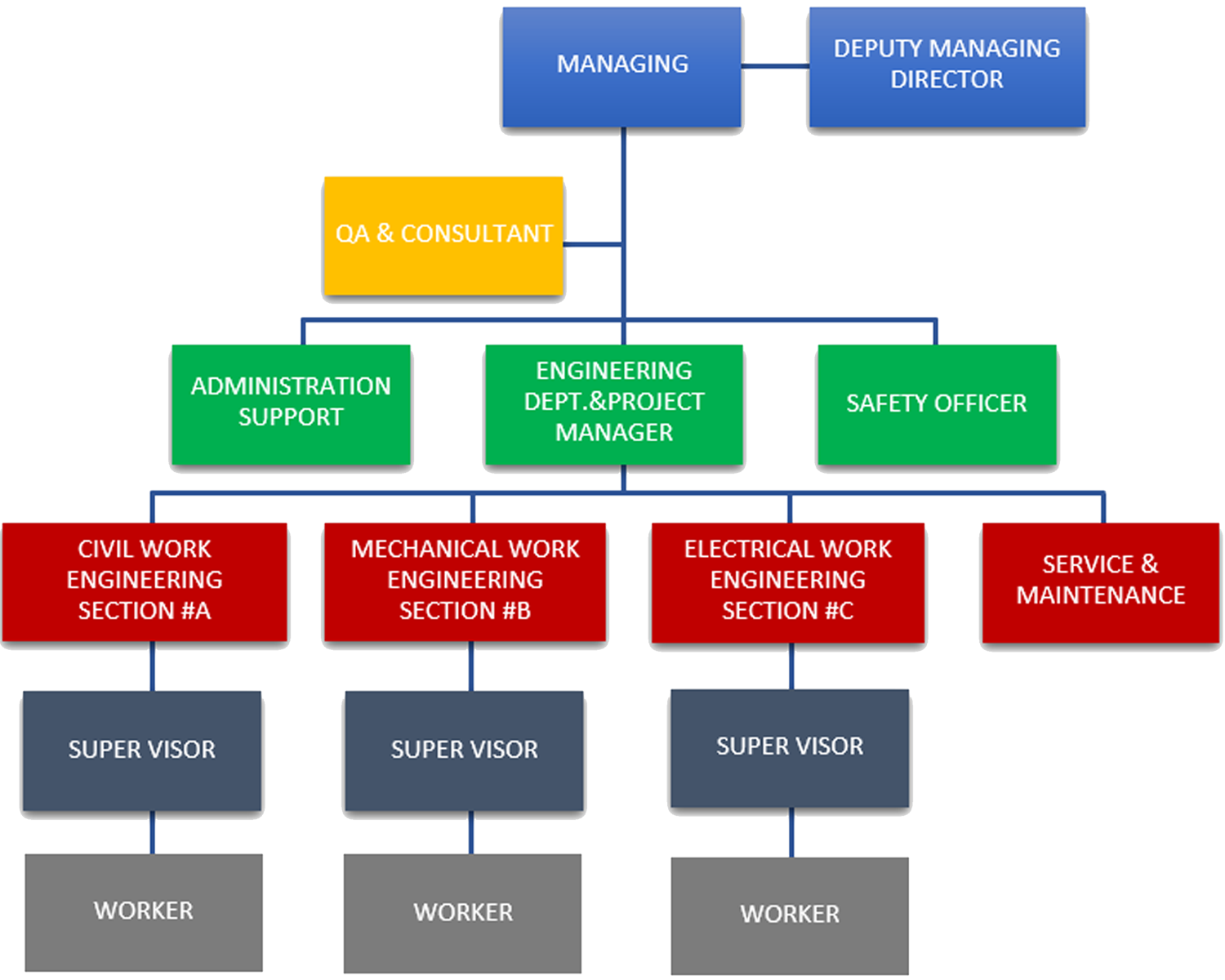

Best Design with cost consideration.

When our team is fully aware of the needs of our customers, the engineering team begins to design the cleanroom and other related systems according to the Layout received from the customer. Moreover, to help customers save costs in the long run, for example, energy-saving, we include the design that will help the customer receive a high-quality cleanroom at a reasonable price.

DEVELOP

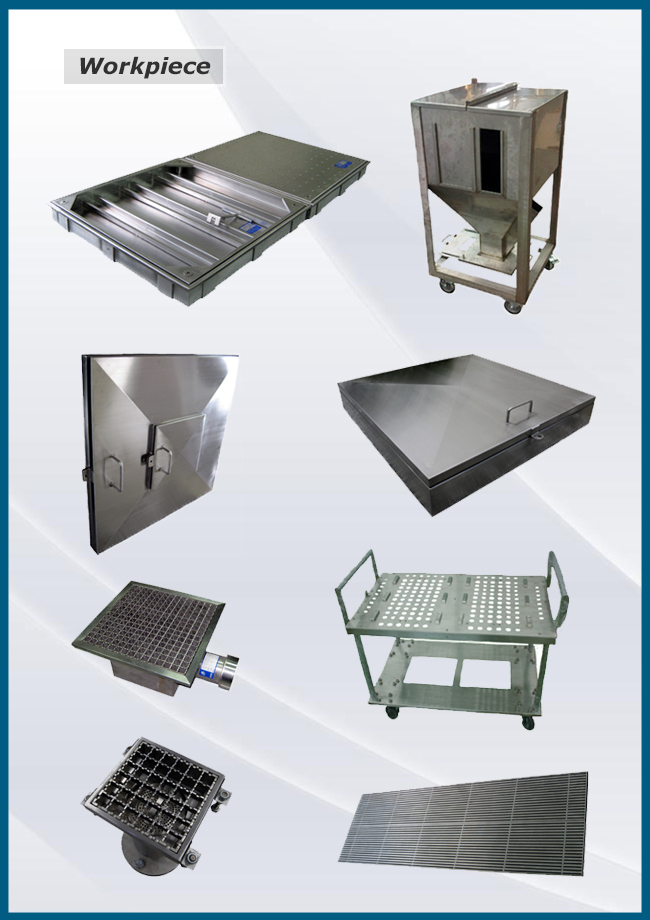

Built from high quality materials by qualified labour.

In the construction process, we will use quality materials and equipment. According to the use of customers to provide the clean room with the highest quality in addition to considering the quality of materials and equipment, we also pay special attention to safety during work. Our workers have received training from work safety officers. Always before going to work to prevent and reduce accidents during the initial operations, including periodic inspections throughout the construction project.

DELIVER

Commissioning before hand-over.

We must test the system based on the NEBB standard as a guideline and will be able to deliver the work to the customer after passing the test only to ensure that the customer's clean room works efficiently according to the conditions specified before construction.

In testing the system, we will divide it into 3 levels:

1. As-Built (Testing while Clean Room is empty)

2. At-Rest (Testing where the machine or production equipment is in the cleanroom)

3. Operational (Testing while Clean Room is in the production process)

The company also provides after-sales services for 1 year to ensure customers are confident in the quality and standards of the company.